TAURUS 3 BLADE

|

Taurus 3 Blade Kits All Taurus 3 blade kits come with one blade and two orange groove grommets. |

|

ALL NEW! DICHROIC BLADE Just for cutting thin Dichroic Glass. This blade has the popular slim blade design with a fine diamond grit that will not chip the delicate dichroic finish! Also works well with iridescent coated glass allowing you to form intricate shapes with perfect edges. Clean edges mean lower temperatures and faster firing times for kiln fired jewelry creating a clean professional look. Buy it now |

| STANDARD BLADE For general use, Omni-directional. The Standard blade gives you strength as well as versatility in all materials. Because the blade is round you have the ability to cut in any direction. The 360 degree diamond coating allows the blade to cut quickly while grinding the edge, leaving it smooth. Buy it now |   |

|

Separating Blade For internal cuts, omni-directional. The Separating blade is the same size as the Standard blade and has exactly the same cutting action. The difference is that the Separating Blade is made from a stainless steel wire that is coated with the same high quality process as all our blades and then has a coupling attached to it which is also coated for protection and smooth action. This blade gives you the ability to open the blade, slide it through, reattach and make internal cuts with no entry point. Buy it now |

| Slim Blade For the most intricate designs, omni- directional. The Slim blade offers the most intricate cutting ability of all our “Ring Blades”. Because of the Slim blade’s diminutive size, it has greater ability to create intricate designs and is ideal when cutting non-ferrous metals but at the same time takes away strength so it is recommended only when its size is beneficial. Buy it now |   |

|

Mega Blade For dense materials. Because of its “tear drop” shape, the Mega Blade is our strongest blade ever. To date, no one has been able to break one. This blade is used differently than our Omni- directional blades. It is cuts mainly on the front and back, so to create a curve you will guide the material around the blade. The Mega blade is so rigid that it has the ability to damage the saw itself if used improperly by pushing too hard. So keep in mind the “golden rule” to let the saw do the cutting and do not force the material. Buy it now |

| Slicer Blade Thinnest kerf ever for Taurus 3. The Slicer blade is ideal when removing the least amount of material is desired. This blade gives you the ability to use more of your material and as a byproduct actually cuts faster than any of our “Ring Blades”. It is highly recommended for use with our Super Slicer. The Slicer blade is flat, giving it strength when cutting forward and backward, because of this, the cutting will only be from the front and back. Cutting from the sides will not only be very slow but will damage the grommets. Buy it now |   |

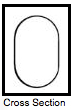

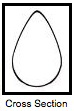

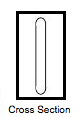

| The Magnificent 7 Blades of the Taurus 3 What Are They All About? There are 7 blades available for the Taurus 3 ring saws and there are often questions arising as to what they are for, how long they last, and how to use them. So we are writing this article to ive a summary of all of them and their many uses. There are now seven blades to choose from.There are universal truths about all of the blades that hold true for all of them. 1) All blades cut the same materials: glass, tile, stone, shell, nonferrous metals, hard plastics such as acrylic and lexan, and anything that has a similar density to these materials. 2) All blades use the same belt and grommets. Blades are interchangeable with the same belt and grommets and do not need to be changed unless they are excessively worn. 3) Always let the blade do the cutting. Forcing the blade through the material in a hurry will not only cause a slower cut but can also shorten the blade life. There is an optimum speed for each blade in each material; you can feel it while you are cutting. Sensitivity to this causes extremely long blade life Defined it is that point at which you get maximum cutting speed for minimal pressure. The Magnificent Seven Serious Blades Note: When describing blade abilities it is wise not to confuse the ability of a blade to cut a certain material greater thickness once in awhile as opposed to that same blade being used to cut only that thickness all the time. For this description we will refer to blade capacity vs. normal use. When we speak of blade shape it is what is called a cross section which is like snipping off a piece of the blade and looking directly at its end. Standard Blade – (part# 1042) Stained glass pattern and all around multi purpose cutting blade. Its action is omni-directional. This is to say that it cuts the same speed and kerf, (swath left by the blade), in any direction. This blade was the first blade to be put on saws and makes pattern cutting very easy because the user does not have to turn the piece while cutting but simply move it in any direction. Blade Shape: Round .072 Diameter (note 1/16″ equals .063 and 1mm equals .0394) Grit is aggressive. Material Thickness Capacity: 3/8″, normal use is 1/8″ art glass, 1/4″ soft wall tile. What to Avoid: Do not use for ceramic tile, 3/8″ fused glass pieces, or thick material in general. Average Blade Life: 40-60 hours Separating Blade – (part# 1043) This blade is the same as above but t comes apart or cutting out the center of something without using an entrance cut. You must first drill a hole. Consult your DVD for hole drilling instructions. Blade Shape: Round .072 Diameter (note 1/16″ equals .063 and 1mm equals .0394) Grit is aggressive. Material Thickness Capacity: 3/8″, normal use is 1/8″ art glass, 1/4″ soft wall tile. What to Avoid: Do not use for ceramic tile, 3/8″ fused glass pieces, or thick material in general. Average Blade Life: 40-60 hours Mega Blade – (part# 1045) This heavy duty blade is hungry for whatever you can feed it. It is almost unbreakable so it is great for class settings. It has an opinion about which way it likes to cut because of its shape which is basically tear dropped. The round part of the tear drop faces outward and the pointed part faces inward. This means it cuts faster when pulling towards yourself and slower pushing away and slowest sideways. Its kerf is the same as a standard blade when pushing and pulling but it leaves a wide swath the same as a standard blade when pushing and pulling but it leaves a wide swath sideways. That said you can cut whatever you can fit into the mouth of the saw and the shape allows for creative shaping. Cutting action is omni-directional in thin material like stained glass but more forward and backward cutting for thicker harder materials. Leaves a smooth edge. Blade Shape: Tear Drop .072 Diameter (front) x .150 (front to back), inside is pointed. Grit is aggressive. Material Thickness Capacity: 3/4″, normal use is fused glass, stained glass, ceramic tile, or stone. You may have to remove the stabilizer foot to use the full 3/4″ capacity. What to Avoid: Do not cut thin dichroic glass as it will chip easily, demonstrate to students its action prior to letting them use it, explaining the tear drop shape and its unique action. Average Blade Life: 50-100 hours Slicer Blade – (part# 1046) This is our thinnest blade and only cuts forward and backward. It can grind slightly left and right, but take your time and it will turn on a dime or smaller. Its action is just like that of a band saw but infinitely better in that you rotate the material into the blade as you are cutting but you can in the middle of the cut without binding and head off in any direction either backwards or forwards. This blade was developed for slicing material quickly with a thin kerf (.040, 1mm) and it is the blade we recommend for use with the Super Slicer, (a jig for slicing pattern bars and rods into thin repeatable wafers). Also it has finer diamond so the cut is even smoother than all the other blades except for the dichro blade. Use this blade with the heavy duty flocked belt to avoid splitting. This blade can turn on a dime and do very intricate designs once you get used to it. Glass fusers love it. Blade Shape: Flat .040 width x .150 length. Grit is fine. Material Thickness Capacity: 3/4″, normal use is for slicing thin wafers in rods and pattern bars, and scroll cutting of fused glass up to 3/8″ thickness. Average Blade Life: 50-100 hours Slim Blade – (part# 1043) Originally developed for the Taurus I thru II.2 series as a thinner version of the standard blade. It has the same dimension as a standard or separating blade front to back but is thinner as you look at it straight on. For this reason it i just as strong as a Standard Blade but can cut quicker front to back and leave a slightly smaller kerf, (.062). It cuts the same as a standard blade left o right and its action is omni-directional. Blade Shape: Oval .062 x .072 (front to back). Grit is aggressive Material Thickness Capacity: 3/8″, normal use is 1/8″ art glass, 1/4″ wall tile. What to Avoid: Do not use for ceramic tile, 3/8″ fused glass pieces, or thick material in general. Average Blade Life: 40-60 hours Dichroic Blade – (part# 1049) NEW! This is the slim blade but coated it in super fine grit so that it does not chip even the thinnest of dichroic glass. Its cut is super quick and leaves the smoothest edge of all of the blades allows the use of lower firing temperatures in the manufacture of jewelry and the like. Neat crisp edges add a note of professionalism with this blade. Its action is omni-directional. Blade Shape: Oval .058 x .072 (front to back). Grit is finest. Material Thickness Capacity: 1/4″, normal use is thinner than normal dichroic or iridized glass. What to Avoid: Do not use for ceramic tile, 1/4″ fused glass pieces, or thick material in general. Average Blade Life: 40-60 hours Speed Blade – (part# 1052) Sometimes known as the inverted Mega blade we turned a mega inside out and made it thinner. The result is a tear dropped shaped blade that is almost unbreakable with the round part on the inside and the point on the outside. Its thinner profile makes it our fastest most aggressive blade yet. When pushing forward into this blade it glides through the thickest toughest materials with ease. It comes with a “Flocked belt” only as this is the only belt that can handle its aggressive nature. Its action is omni-directional in stained glass or soft wall tile and forward and backward for thicker or harder materials. When pushing or pulling the material through with this blade it has a thinner kerf than a Standard, Mega, or Slim blade. (.055). Blade Shape: Tear Drop .055 inside x .150 (front to back). Grit is aggressive. Material Thickness Capacity: 3/4″, normal use is fused glass, stained glass, ceramic tile and stone. Note: you will have to remove the stabilizer foot to use the full 3/4″ capacity. What to Avoid: Do not cut thin dichroic glass as it will chip easily. Demonstrate to students its action prior to letting them use it, explaining the tear drop shape and its uniqueness. Average Blade Life: 50-100 hours |